content body

Food plays a central role in bringing people together for holiday celebrations, whether it’s a large, festive gathering or a simple family meal, and the act of gathering around the table fosters a sense of community and joy — unless that food is tainted with bacteria like salmonella, E. coli or listeria.

Recent foodborne illness outbreaks linked to carrotts, frozen waffles, deli meats and fast food have brought bacteria back into the spotlight, and these incidents are increasing in frequency. But across the campus of Auburn University, researchers from a wide range of disciplines are working to ensure America’s food processing and supply chain systems are safe.

Shine a light on meat

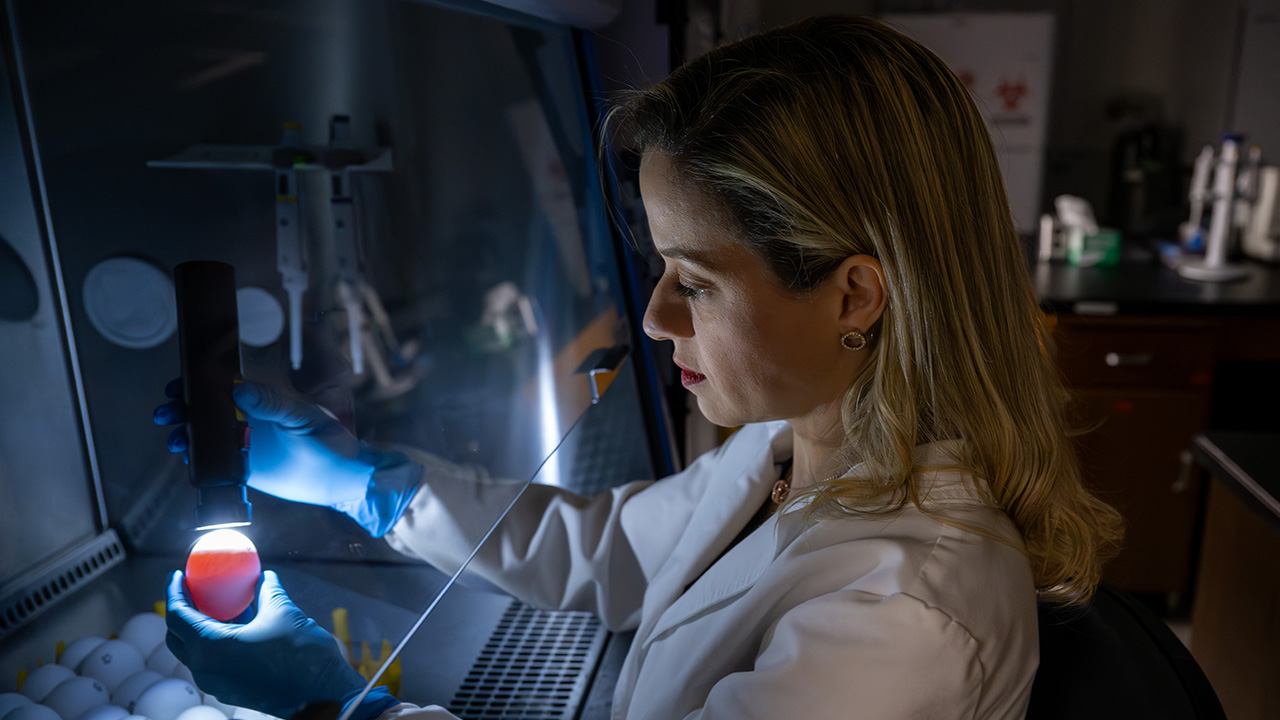

A graduate student in Auburn’s College of Agriculture is shining a light on meat — quite literally. With the help of researchers in the poultry science department, the U.S. National Poultry Research Center and the private company PulseForge Inc., Abigail McConnell is studying whether photonic decontamination, or the use of pulsed light technology, can eliminate food-borne illnesses during poultry processing. McConnell and her team have shown that high-intensity pulses of light, which can include ultraviolet, visible and near-infrared light, can kill bacteria without using chemicals or heat, therefore preserving the quality of the food.

In their first study, McConnell and the team found certain genes in salmonella were changed after exposure to pulsed light. The light treatment caused stress to the bacteria, forcing it to conserve energy by turning off the genes that make it infect humans. In two other studies, they found the use of pulsed light technology was able to eliminate salmonella and a harmful bacteria called Campylobacter when combined with dipping poultry parts in water or peracetic acid, a sterilizing agent commonly used in meat processing.

Preventing avian flu in turkey

Miria Criado, an assistant professor in the College of Veterinary Medicine, is researching ways to prevent and control avian influenza, particularly in chickens and turkeys. Her work focuses on understanding how these influenza viruses evolve and interact with their hosts. Through her research, she hopes to develop strategies to reduce the virus’s impact on poultry, which is crucial for both animal health and the poultry industry.

Criado’s work is especially important given that the poultry industry produces more than 80,000 jobs and $15 billion in revenue in Alabama alone.

Wash up with essential oils

Assistant Extension Professor Camila Rodrigues, supervisor of Auburn’s Produce Safety Lab, is studying whether essential oils can be used for food safety in organic fruit and vegetable production. Rodrigues, with postdoctoral fellow Jessica Pizzo, tested oregano and winter savory essential oils on three different types of lettuce — romaine, crisphead and butterhead — in a postharvest washing system. They found the essential oils were extremely effective in limiting E. coli cross-contamination for all lettuce types and are a healthy and sustainable alternative to traditionally used sterilizing chemicals.

Rodrigues and Pizzo are continuing to research the possibilities of using essential oils to sanitize produce, focusing on finding the best concentrations for different types of produce and bacteria strains and exploring the possible long-term effects on produce quality and sanitization equipment.

Healthy water for Alabama farmers

With the help of doctoral student Zoila Chevez and other researchers in the Produce Safety Lab, Rodrigues is assessing the prevalence of foodborne pathogens in the water Alabama farmers use to grow vegetable crops. There are more than 2,000 produce farms in the state, and if their water sources are contaminated with harmful bacteria including E. coli, salmonella and Shiga toxin-producing E. coli, those foodborne illnesses can get passed on to consumers.

After Rodrigues’ and Chevez’s findings revealed the importance of educating farmers, the Alabama Cooperative Extension System (ACES) created a program called AgWater Safety. Any farmer in the state who uses well or pond water to produce fresh fruits and vegetables qualifies for free microbial testing, technical assistance and educational tools. Extension agents are busy in the field ensuring farmers have access to the resources they need to maintain food safety.

Studying the surface

Ahmed Hamid, an assistant professor of analytical chemistry in the College of Sciences and Mathematics’ Department of Chemistry and Biochemistry, is developing innovative methods and instruments to detect and identify various food poisoning causes, including pesticides and foodborne pathogens.

Hamid and his graduate student Orobola Olajide have successfully used ion mobility mass spectrometry, which separates and measures ions, and computer programs that predict molecular behavior to find pesticides directly on the surface of plant leaves without having to take samples. They’ve also uncovered ways to quickly and accurately tell the difference between harmful and harmless strains of E.coli bacteria. Hamid worked with Pizzo to use these optimized methods to identify various pathogenic bacteria that have caused outbreaks of foodborne illnesses in the past.

Currently, Hamid and graduate student Kimberly Kartowikromo are developing a portable ion mobility spectrometer that can be used for on-site identification of foodborne pathogens.

Safety make sens(ors)

ZhongYeng Cheng, McWane Professor in the Samuel Ginn College of Engineering, is working on the development of new technologies to help improve food safety during production. He and his colleagues developed an electronic sensor that monitors the disinfectant concentration in water used to wash fresh produce, as well as an electromagnetic fluid filter sensor for rapid detection of pathogenic bacteria in water that prevents contaminated food from reaching consumers and contaminated water from being used in irrigation.

Most recently, they created a portable 2D sensing pad that can detect the presence of methyl parathion, a carefully regulated pesticide that can be harmful to the environment and human health. The sensing pad, which was created from cellulose nanofibers and luminescent metal-organic frameworks, glows under UV light and either dims or goes out when it encounters methyl parathion, indicating how much pesticide is present. While agricultural producers are careful with the application of methyl parathion, this technology can help ensure pesticide levels are within safe and legal limits and have not spread to adjacent water sources or other plants.

He and his colleagues hold 10 U.S. and European Union patents on the sensors they’ve invented, one of which was selected by the Food and Drug Administration as one of five top technologies for future food safety.